Slide Gate Plates and Inserts

| Alumina carbon (OASP-1) |

Alumina zirconia carbon (OASP-12) |

Alumina spinel carbon (OASP-14) |

Magnesia spinel carbon (OASP-34) |

|

| Recommended for steel quality | Medium and high carbon steel |

Medium and high carbon & alloy steel |

Stainless steel | Calcium treated low carbon steel |

| TYPICAL CHEMICAL ANALYSIS (LOSS FREE BASIS) | ||||

| Al2O3 (%) | 84.0 | 75.0 | 83.0 | 9.5 |

| Fixed carbon (%) | 5.0 | 5.0 | 6.0 | 5.0 |

| ZrO2 (%) | - | 8.0 | - | - |

| MgO (%) | - | - | 6.0 | 80.0 |

| SiC (%9 | 2.0 | 2.0 | - | - |

| TYPICAL PHYSICAL PROPERTIES | ||||

| Apparent porosity (%) | 6.0 | 6.0 | 6.0 | 6.0 |

| Bulk density (gm/cc) | 3.20 | 3.18 | 3.20 | 2.95 |

| Cold crushing strength (kg/cm2) | 1000 | 1000 | 900 | 1000 |

| Hot MOR (kg/cm2) at 14000 C | 160 | 150 | 100 | 125 |

Well Blocks

Typical chemical analysis and physical properties

| Quality | Apparent porosity (%) |

Bulk density (gm/cc) |

CCS at 110°C/24 hrs. (kg/cm2) |

Al2O3 (%) |

Fe2O3 (%) |

MgO (%) |

| ORIENT W/B-75 | 18.2 | 2.82 | 660 | 76.2 | 2.3 | - |

| ORIENT W/B-85 | 17.0 | 2.88 | 550 | 86.0 | 0.81 | - |

| ORIENT W/B (SUPER) | 18.5 | 3.05 | 550 | 90.8 | 0.3 | 4.8 |

Nozzles

Typical chemical analysis (loss free basis) and physical properties

| Quality | Apparent porosity (%) |

Bulk density (gm/cc) |

CCS at 110°C/24 hrs. (kg/cm2)1 |

Al2O3 (%) |

MgO (%) |

Fe2O3 (%) |

| Upper Nozzle | ||||||

| 85% Aluminia | 20.0 | 3.00 | 500 | 85.0 | - | 0.30 |

| Aluminia spinel | 18.0 | 3.05 | 550 | 91.0 | 4.8 | 0.30 |

| Magnesia spinel carbon | 6.0 | 2.90 | 550 | 24.0 | 80.0 | 0.30 |

| Aluminia carbon | 15.0 | 2.70 | 1000 | 80.0 | - | 0.50 |

| Lower Nozzle | ||||||

| 85% Aluminia | 20.0 | 3.00 | 500 | 85.0 | - | 0.30 |

| Aluminia carbon | 15.0 | 2.70 | 1000 | 80.0 | - | 0.20 |

Mortars and sealants

Typical chemical analysis (loss free basis) and physical properties

| ITEM | Grading (mm) |

Service Tep. °C |

Setting | Al2O3 (%) |

Fe2O3 (%) |

Application |

| ORIENT 90 AM | 0-0,2 % | 1800 | Chemical/ Heat |

90±2 | 0.2 | For fixing slide plates, collector nozzles, inner nozzles and purging plug |

| ORSEAL-97 | Paste (Ready to use) |

1800 | Chemical/ Heat |

97±2 | 0.2 |

This prevents leakage of molten metal |

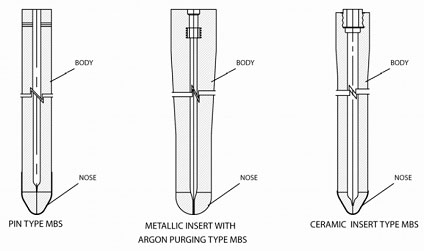

Monoblock Stoppers

|

| Body | Nose | ||||||||

| Quality | OE | OL | OD | OM | OO | ON | OS | OI | OU |

| STEEL GRADE | |||||||||

| Plain carbon/normal grades | - | - | √ | √ | - | - | - | - | - |

| Aluminium killed | √ | - | √ | √ | - | - | - | - | - |

| Calcium treated | √ | √ | √ | - | - | - | √ | - | √ |

| Stainless | √ | √ | √ | - | √ | √ | - | √ | √ |

| High manganese | √ | √ | - | - | √ | - | - | - | √ |

| Body | Nose | ||||||||

| Quality | OE | OL | OD | OM | OO | ON | OS | OI | OU |

| TYPICAL CHEMICAL ANALYSIS (%) | |||||||||

| Al2O3 | 49.4 | 61.1 | 49.3 | 70.0 | 73.2 | 70.5 | 10.2 | 59.3 | - |

| SiO2 | 18.7 | 9.5 | 18.8 | 4.7 | 7.3 | 12.2 | - | 6.6 | - |

| MgO | - | - | - | - | - | - | 65.3 | - | 73.4 |

| ZrO2 | - | - | - | - | - | - | - | 4.2 | - |

| C | 28.2 | 27.6 | 28.4 | 21.4 | 17.5 | 16.5 | 22.1 | 24.3 | 22.2 |

| Body | Nose | ||||||||

| Quality | OE | OL | OD | OM | OO | ON | OS | OI | OU |

| TYPICAL PHYSICAL PROPERTIES | |||||||||

| Apparent porosity (%) | 16.4 | 16.7 | 16.1 | 16.6 | 18 | 17.5 | 17.5 | 16.7 | 17.4 |

| Bulk density (gm/cc) | 2.4 | 2.51 | 2.41 | 2.65 | 2.68 | 2.60 | 2.55 | 2.65 | 2.57 |

| C.M.O.R. (kg/cm3) | 85 | 90 | 80 | 90 | 95 | 85 | 80 | 75 | 85 |

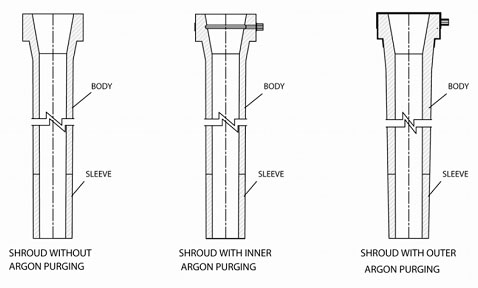

Ladle Shrouds

|

| Body | Sleeve | |||

| Quality | OC | OF | OX | OG |

| STEEL GRADE | ||||

| Plain carbon/normal grades | √ | √ | √ | √ |

| Aluminum killed | √ | √ | √ | - |

| Calcium treated | - | √ | √ | √ |

| Stainless | √ | √ | √ | √ |

| High manganese | √ | √ | √ | √ |

| Resuable | √ | - | - | √ |

| High performance | - | √ | √ | - |

| Body | Sleeve Mix | |||

| Quality | OC | OF | OX | OG |

| TYPICAL CHEMICAL ANALYSIS (%) | ||||

| Al2O3 (%) | 45.8 | 50.5 | 9.8 | 50.8 |

| C (%) | 34.4 | 30.6 | 19.4 | 34.8 |

| SiO2 | 17.2 | 14.5 | - | 12.0 |

| ZrO2 (%) | - | - | 67.4 | - |

| Body | Sleeve Mix | |||

| Quality | OC | OF | OX | OG |

| TYPICAL PHYSICAL PROPERTIES | ||||

| Apparent porosity (%) | 16.4 | 13.1 | 15.3 | 15.6 |

| Bulk Density (gm/cc) | 2.35 | 2.45 | 3.5 | 2.38 |

| C.M.O.R (kg/cm2) | 70 | 70 | 120 | 75 |

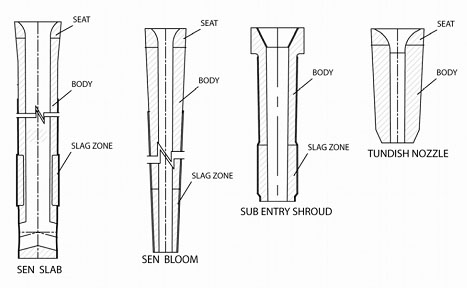

Sub-Entry Nozzles/ Sub-Entry Shrouds/ Tundish Nozzles

|

| Seat | Body | Slag Zone | Sleeve | |||||||||||

| Quality | OM | OO | OS | OH | OB | OH | OJ | OW | OK | OX | OY | OZ | OX | OZ |

| STEEL GRADES | ||||||||||||||

| Plain carbon / normal grades | √ | - | - | - | √ | - | V | - | V | V | - | - | - | - |

| Aluminum killed | √ | - | √ | √ | √ | V | V | - | - | V | - | - | - | - |

| Calcium treated | - | √ | √ | - | √ | V | V | - | - | - | V | V | V | V |

| Stainless | √ | √ | - | - | √ | - | V | V | V | - | V | - | - | V |

| High manganese | - | - | - | - | √ | - | V | - | V | - | V | V | V | V |

| Seat | Body | Slag Zone | Sleeve | |||||||||||

| Quality | OM | OO | OS | OH | OB | OH | OJ | OW | OK | OX | OY | OZ | OX | OZ |

| STYPICAL CHEMICAL ANALYSIS (%) | ||||||||||||||

| Al2O3 | 70.0 | 73.2 | 10.2 | 55.7 | 43.0 | 55.7 | 60.3 | 24.2 | 60.3 | - | - | - | - | - |

| SiO2 | 4.7 | 7.3 | - | 12.2 | 26.8 | 12.2 | 10.5 | 22.2 | 10.5 | - | - | - | - | - |

| MgO | - | - | 65.3 | - | - | - | - | - | - | - | - | - | - | - |

| ZrO2 | - | - | - | - | - | - | - | 30.6 | - | 67.4 | 79.3 | 80.5 | 67.4 | 80.5 |

| C | 21.4 | 17.5 | 22.1 | 26.7 | 26.4 | 26.7 | 26.2 | 16.5 | 26.2 | 19.4 | 14.7 | 11.8 | 19.4 | 11.8 |

| Seat | Body | Slag Zone | Sleeve | |||||||||||

| Quality | OM | OO | OS | OH | OB | OH | OJ | OW | OK | OX | OY | OZ | OX | OZ |

| TYPICAL PHYSICAL PROPERTIES | ||||||||||||||

| Apparent porosiy (%) | 16.6 | 18.0 | 17.5 | 17.7 | 16.6 | 17.7 | 17.4 | 15.4 | 17.4 | 15.3 | 15.4 | 15.5 | 15.3 | 15.5 |

| Bulk density (gm/cc) | 2.65 | 2.68 | 2.55 | 2.48 | 2.38 | 2.48 | 2.55 | 2.63 | 2.50 | 3.50 | 3.75 | 3.78 | 3.50 | 3.78 |

| C.M.O.R. (kg/cm ) | 90 | 95 | 80 | 75 | 80 | 75 | 90 | 95 | 90 | 120 | 140 | 150 | 120 | 150 |

Tape Hole Sleeves

| Sleeves | Blocks | |

| Quality | OT | OV |

| TYPICAL CHEMICAL ANALYIS (%) | ||

| MgO | 76.2 | 82.4 |

| C | 17.5 | 12.5 |

| Al2O3 | 4.5 | 4.5 |

| Sleeves | Blocks | |

| Quality | OT | OV |

| TYPICAL PHYSICL PROPERTIES | ||

| Apparent porosity (%) | 2.5 | 7.6 |

| Bulk density (gm/cc) | 2.91 | 2.78 |

| CCS (kg/cm2) | 400 | 450 |

| ZN-96 SD | ZN-95 D | ZN-95 N | |

| TYPICAL CHEMICAL ANALYSIS (%) | |||

| ZrO2+HFO2 | 96.0 | 95.5 | 95.0 |

| MgO | 2.0 | 2.5 | 3.0 |

| SiO2 | 0.3 | 0.5 | 0.5 |

| TiO2 | 0.1 | 0.1 | 0.1 |

| Al22O3 | 0.1 | 0.1 | 0.1 |

| Fe2O3 | 0.05 | 0.1 | 0.1 |

| ZN-96 SD | ZN-95 D | ZN-95 N | |

| TYPICAL PHYSICAL PROPERTIES | |||

| Apparent Porosity% | 2.5 | 6.0 | 16.0 |

| Bulk Density (gm/cc) | 5.5 | 5.2 | 4.7 |

| ZN-65 | ZN-71 | AGN-85 | |

| TYPICAL CHEMICAL ANALYSIS (%) | |||

| Al2O3 | - | - | 86.0 |

| ZrO2 | 64.0 | 71.0 | - |

| C | - | - | 4.0 |

| SiC | - | - | 5.0 |

| Cr2O2 | - | - | 3.0 |

| ZN-65 | ZN-71 | AGN-85 | |

| TYPICAL PHYSICAL PROPERTIES | |||

| Apparent porosity (%) | 20,0 | 20.0 | 5.0 |

| Bulk density (gm/cc) | 3.70 | 3.8 | 3.15 |